Steam Boiler Machines Steam Boiler is a special machine which is used to heat water to produce steam. This steam is used for running various machines and tools and it is very important. From producing goods in factories to assisting farmers with the farm work & to build in construction, steam boilers are necessary for the job. In order to ensure a steam boiler operates effectively, we must have an inkling of what optimizes or hinders its performance.

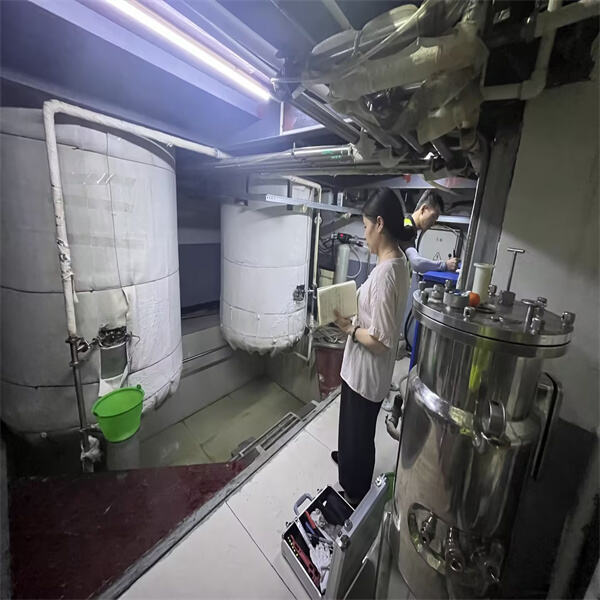

Water quality is one of the most important factors affecting the performance of a steam boiler. Water quality inside the boiler is one of the major reasons why some of the boiler fail. Polluted H2O can block up the system, activate corrosion, or even tear the device down. And, that is why, it is extremely essential to make use of water devoid of any dust, loosened soil and also all the harmful compounds. If water is of high quality, then boiler operates fine and works for a longer time without any problem.

Boiler pressure is also one of the major factors that affect the performance of a steam boiler plant. Steam boilers have to maintain a particular pressure that allows enough steam to be generated to operate the machines. Aggressive pressure can be lethal, as well as crack the range. Too low of a pressure will not allow the boiler to produce enough steam energy to be functional. It's like a seesaw if one side is too heavy it won't function. So, maintaining the pressure is very important for the proper functionality of the boiler.

Proper maintenance of steam boilers is a big deal since they can get damaged if ignored. It means keeping up with regular maintenance, such as cleaning the boiler, replacing old or worn-out components, and checking the water quality and pressure regularly. If regular care is likened to a boiler service, then this is like going for the Doctor for a general check-up and ensuring everything is running smoothly.

And, do take advantage of them in the proper manner. Avoid overloading it with excessive water or steam at the same time. Every boiler comes with a limit, and the appropriate utilization helps avoid issues. The pressure also needs to be just right—not so high as to cause damage or breakdown and not so low as to lead to breakdown, too. Its success depends on knowing how to use the boiler accurately.

To make steam boilers function properly and in an efficient manner, there are a few important properties attached to the system. And one of those features is a decent burner. The burner is the portion of the boiler that burns the fuel to heat the water Less fuel consumption www smokeless fire pits uk with stable heat output will be here that high quality burner, the low fuel consumption is also www smokeless fire pits uk better for our environment. Not only is the steam generated soda-efficient but it also plays an important role in pollution control.

If your machines require a lot of steam to operate, you may want a boiler that is large enough to maintain that demand. However, if you only require small amounts of steam, a smaller boiler could suffice. Always make it a point to consult a steam boiler expert to understand which steam boiler size is ideal for your needs. They can advise you on how to ensure that you make a wise choice.

မူပိုင်ခွင့် © Hubei Nobeth Machinery Manufacturing Co., Ltd. All Rights Reserved